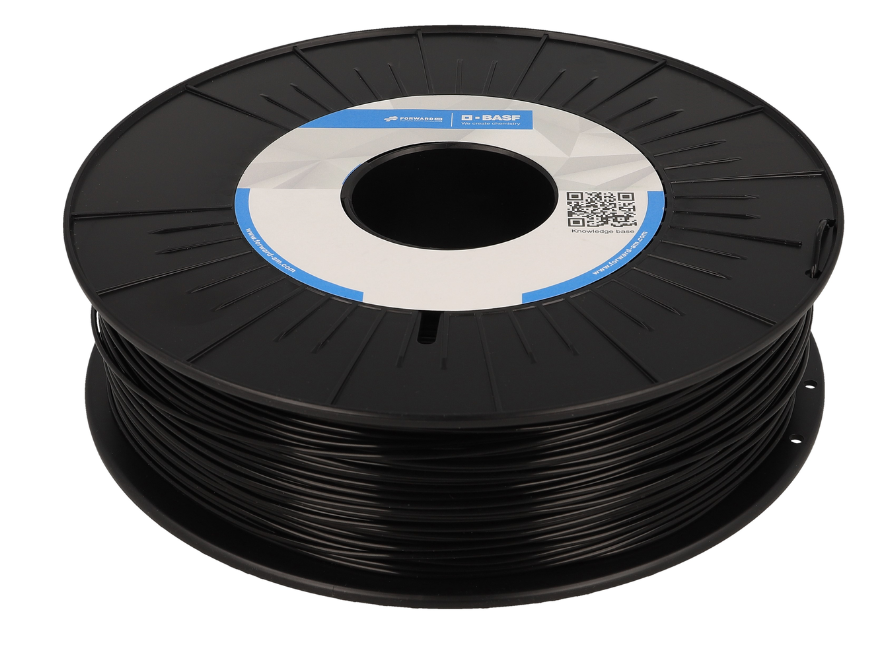

Ultrafuse® PLA Tough

Ultrafuse® PLA Tough is a highly versatile biocompatible and biobased material specially developed for the needs of professional users. It effortlessly accommodates validated high printing speeds up to 300mm/s1, without the need for any hardware adjustment while offering an exceptional surface finish and an impressive impact strength. Moreover, it boasts a notably high success rate for large print jobs, ensuring a straightforward and cost-effective printing process.

720% tougher than standard PLA

Ultrafuse® PLA Tough can be an alternative to ABS as it is more sustainable, strong, and easy to print. As it is compatible with water-soluble BVOH support material, this biocompatible material which exhibits an impressive impact strength – 720% higher than standard PLA – is the perfect solution for printing complex geometries for demanding high-volume applications.

Furthermore, Ultrafuse® PLA Tough parts can be enhanced by annealing the part in a separate process step, which can increase the toughness up to 230% and its heat resistance by 257%.

Example Applications

- Jigs & fixtures

- Orthotics and Protheses

- Functional Prototyping

With Ultrafuse® PLA Tough Filament, you can achieve sustainable, cost- and time-saving production of large components at rapid speeds while maintaining impeccable surface quality. Elevate your designs and projects to PRO levels with a filament that guarantees outstanding performance, reliability, and consistency.

Material Properties

- Tensile strength (MPa): 40 (xy), 28 (zx)

- Young´s modulus (MPa): 2672 (xy), 2576 (zx)

- Elongation at break (%): 7.4 (xy), 2.2 (zx)

- Impact Strength (kJ/m2): 33 (xy), 34 (xz), 10 (zx)

- Heat Resistance when Annealed (°C): 157 Vicat 10N, 94 HDT B at 0.45MPa

Printing Guidelines

- Nozzle Temperature: 200-220 °C

- Bed Temperature: 50 – 70 °C

- Bed Material: Glass

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 40 -3001 mm /s

1. Fast printing might require an additional increase of the nozzle temperature; the stated printing speed of 300 mm/s is based on current validations. As equipment and technology continues to evolve, it is possible that even higher printing speeds may be attainable in the future.

Recenzije

Još nema recenzija.